CHECK OF THE DIMENSION OF THE MOTOR AND THE ELECTRONICS

Once the motor and the transmission are roughly chosen, it is necessary to carry out an analytic analysis of the application. Such a check is immediate for those applications featured by almost steady or variable speed and load on longer times than the time constant typical of the motor (and the electronics). In such a case, it is sufficient to verify that the maximum load ranges between the capacity stated for both the motor and the electronics. On the other hand, in case of applications where the load varies according to a quick cycle, it will be necessary to proceed as follows:

- plot the diagram illustrating speed/time of the cycle, taking into consideration that the achievement of a precise position or speed requires, besides to the time imposed by the limit accelerations of the system, a period of settling equal to 2-3 time the reverse of the pass-band of the system (refer to applications 1 and 2);

- quote inertia and loads of the system to the motor shaft;

- calculate the cycle of the accelerations and therefore the inertial torque [acceleration x (motor inertia + load inertia referred to the motor shaft)], without omitting to consider the inertia of joints, conic fittings and intermediate driving members;

- by adding up the load to the motor shaft with the inertial torque, a torque/time diagram in the cycle will be obtained;

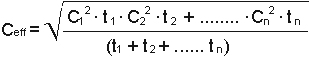

- calculate from the torque/time diagram the average square value of the torque: by making up the cycle in t1, t2 ….tn segments, if the torque released in every segment of the cycle are C1,C2….Cn respectively, the average quadratic, or effective torque in the cycle is:

-

calculate the average quadratic, or efficient speed, in the cycle, eff with the same formula;

-

calculate the average torque in the Cave cycle;

-

calculate the maximum life of the highest torque in the tomax cycle;

-

calculate the torque required at the highest Cwmax speed;

-

calculate the highest Cpk torque. The resulting data will have to be compared to the limits of the motor and the electronics.

-

calculate the highest Cpk torque. The resulting data will have to be compared to the limits of the motor and the electronics.

-

calculate the highest Cpk torque.The resulting data will have to be compared to the limits of the motor and the electronics.

The resulting data will have to be compared to the limits of the motor and the electronics.

CORRELATED PAGES

DECLARATION OF CE CONFORMITY

Referred to EC Low Voltage Directive 73/23/CEE

We hereby certify that the motors of the ULTRACT and LYRA line have been designed, manufactured and tested according to the EC Low Voltage Directive 73/23/CEE under the responsibility of:

R.C.V. s.r.l.

V. Cavour, 7 z.i.

10070 ROBASSOMERO (TO)

Applied standards are the following:

IEC 72/1, 34/1, 34/5, 34/11

EN 60034 – 1 + VAR A1 + VAR A2

EN 60529

EN 50262

CEE 73/23

HOW TO REACH R.C.V.

R.C.V. is conveniently located in the industrial area of Robassomero, a town on the outskirts of Turin.

Coming from Aosta (A5) and Milan (A4) motorway, take the Turin highway – southward direction, if arriving from the Fréjus (A32), from Piacenza (A21) or from Savona (A6), drive north.

Exit “Venaria – stadio” and turn left at the lights, direction to Lanzo.

Cross the built-up area of Venaria and drive the S.P. (Provincial Road) No. 1 for 8 km approximately, you will run along the perimeter wall of the Regional Parc of “La Mandria”, up to the lights of the industrial area of Robassomero.

Turn right, at the first street turn right again and you will reach Cavour street where R.C.V. is located.