GENERAL DESCRIPTION OF ULTRACT TYPE SERVOMOTORS

Ultract are the brand names identifying the results of a specific planning covering a wide range of brushless servomotors (three-phase synchronous motors with sintered rare earth permanent magnets, developed with radial air gap). This huge product family has been rationally split up into 6 dimension groups (sizes), which have all been evaluated to offer the most suitable solution to any technical, functional and room requirements. The whole design has been focusing on the operation of the most advanced electronic control machinery with highest control passband.

Ultract servomotors by R.C.V. are featured by the highest ratio dimension/torque and dimension/power and can attain almost absolute rotating uniformity. Thanks to these top quality machinery, the limit imposed by the traditional mechanical drives are easily overcome and an extended range of gear applications is assured. Most success must be attributed to the sinusoidal control system and to the new absolute encoders with maximum resolution of 8 millions points/revolution, specifically developed for this kind of motor.

The cogging parasitic torque (cogging) and the ripple parasitic torque (ripple) are kept down to the minimum value thanks to the specific devices studied and developed by R.C.V.

The application fields are the most disparate, ranging from the quick positioning of light pieces, for applications in robotized manipulators, in general for the replacement of DC and stepper motors, up to gear installations on huge processing line, with the aim to achieve the progressive elimination of the transmission axis. The industrial sectors involved vary from the mechanics to the plastic moulding, from the textiIe to the paper industry, from the aerospace to the nautical field, from the training and education to the civil engineering …

Ultract servomotors are available in 6 dimensional sizes with extension in length to increase the yield power: starting from the smallest 70W micro positioning device only 169mm in length up to attain an actual 300kW giant 890mm in length.

- UL04 (85mm square shell)

– 6 models from 1,3 to 8,2 Nm - UL05 (100mm square shell)

– 7 models from 2,0 to 13,0 Nm - UL07 (145mm square shell)

– 9 models from 6,3 to 45,0 Nm - UL10 (200mm square shell)

– 6 models from 30 to 105 Nm - UL10F servo-ventilated (224mm square shell)

– 6 models from 48 to 160 Nm - UL13 (264mm square shell)

– 7 models from 92 to 334 Nm - UL13F servo-ventilated (294mm square shell>)

– 7 models from 121 to 445 Nm

R.C.V. servomotors are manufactured with:

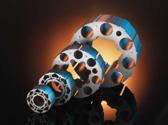

- Sintered rare earth permanent magnets (Nd Fe B) with mechanic assembly (no gluing), providing a dual protection to avoid any damages caused by environmental agents

- Stator manufactured with low leakage magnet laminations at reduced thickness

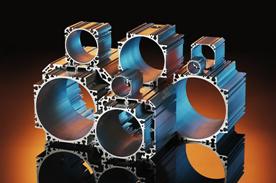

- Light alloy casings with particular grooved profile to improve cooling

- class F motor insulation according to DIN 0530

- windings both for 220-240v and 380-440v feedings (all featuring class H insulation according to DIN 0530) for any size up to 07 and exclusively 380-440v for larger sizes

- built-in thermal protection by means of PTC at 130°C

- heavy-duty bearings lubricated to last at least 30.000hv

- Minimum IP54 protection, upon request IP65 is available, too

- Any transducer: Hall probe – resolver – encoder

- Particularly sturdy structure thus avoiding troublesome vibrations and assuring long life.

- Components are supplied exclusively by primary companies

- for the control or power electric connections we can choose among different solutions, from the most disparate clutch connectors to the traditional terminal board.

- In case a parking brake is required, we are used to fit KENDRION permanent magnet brakes produced by Binder Magnete, worldwide known leading manufacturer.

- The larger UL10 and 13 sizes studied for gear applications on huge processing lines fit a cast-iron front cap and they can be supplied in the specific servo-ventilated version.

ULTRACT

CORRELATED PAGES

ULTRACT

TECHNICAL DATA SHEET

![]() Overall dimensions and safe operating areas – UL04

Overall dimensions and safe operating areas – UL04

HOW TO REACH R.C.V.

R.C.V. is conveniently located in the industrial area of Robassomero, a town on the outskirts of Turin.

Coming from Aosta (A5) and Milan (A4) motorway, take the Turin highway – southward direction, if arriving from the Fréjus (A32), from Piacenza (A21) or from Savona (A6), drive north.

Exit “Venaria – stadio” and turn left at the lights, direction to Lanzo.

Cross the built-up area of Venaria and drive the S.P. (Provincial Road) No. 1 for 8 km approximately, you will run along the perimeter wall of the Regional Parc of “La Mandria”, up to the lights of the industrial area of Robassomero.

Turn right, at the first street turn right again and you will reach Cavour street where R.C.V. is located.